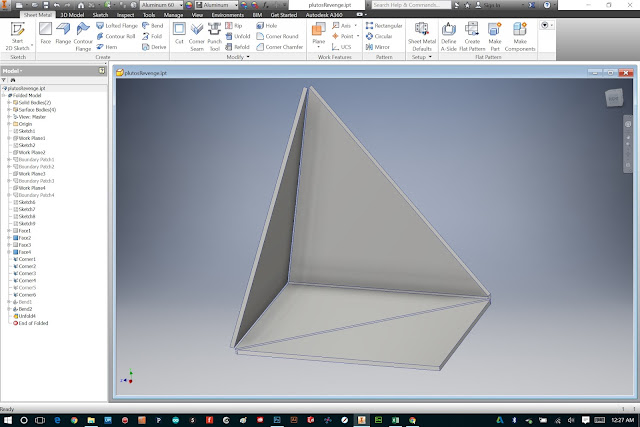

After creating a sheet metal cad model in Autodesk Inventor (as I outlined in Part One) I wanted to add tabs and holes for fasterners, so when I build this thing with real materials it will be sturdy and will stay together without any tape or glue or anything like that.

Below I have outlined my process for adding tabs and holes for fasteners (m3 bolts in this case).

First, it is going to be helpful to unfold one side of my vessel so I can easily see inside as I draw the tabs.

I selected the bottom face as my stationary reference, and picked one of the edges to unfold.

Next, I have to create an offset plane to create a sketch for my first tab. I don't want to sketch directly on the face the tab will meet with, because Autodesk doesn't like it when two faces exist in the exact same location (and the real world doesn't exactly allow for this either!)

So I just create a plane offset .01 inches from the inside face.

Next, I sketch my tab. Because I'm drawing from an angle, it is important to make use of constraints and dimensions to make sure everything lines up correctly. From this awkward perspective, I can't rely on eye-balling any geometry.

In addition, I dimensioned my "holes" to be 3mm in diameter, since this is the diameter of the fasteners I'll be using when I build this vessel.

After sketching my tab, I create a "face" feature from it, and select "new solid".

The resulting face, pictured above.

Next, I select the two adjacent edges to create a bend for the new face.

Since the holes I drew were only reference geometry (or construction lines as I usually call them) I am going to select that sketch and share it, so I can easily reference it again.

I sometimes find it helpful to change the visual style to "Shaded with Hidden Edges" so I can see behind obstructions.

Now it is time to add holes for fasteners. I create a new sketch on the face of the tab I created...

And re-draw my 3 mm holes, referencing the original sketch I drew.

I then create a "cut" feature from that sketch...

And select "All" for extents, making sure the cutting direction is correct.

To make sure it cuts through the tab AND the surface the tab will fasten to, I select "Solid" and then click on the adjacent surface...

Resulting in holes that go through the tab, and the side of the vessel. This will allow me, when I build this thing in sheet aluminum, to fasten it together with bolts.

I repeat this whole process for all three faces. Tab, holes, tab holes. Yay! Fun!

And in the end. unfold the vessel. My sheet metal template is complete!

Soon I will be actually fabricating this thing... check out the next step here.

I have gone through project management templates, but sheet metal templates are simply new for me. it is good to know about the technology of this level. your blog is simply awesome.

ReplyDelete